Burr-free drilling with ECM

Electrochemical drilling includes the introduction of geometries into the depth of work pieces by means of electrochemical sinking. Typically, the tool is then moved towards and/or into the work piece so that stationary process parameters can be set.

Benefits of process:

- Generation of round and non-round holes of various dimensions

- Feed rates up to 3 mm/min and beyond as a function of material

- Machining of good- and hard-to-machine materials

- Generation of several closely spaced holes at the same time (diameter and position tolerance ± 0.03 mm and better)

- Tangential holes on cylindrical work piece can be made without any problems

- Simultaneous generation of defined edge chamfers on the entry and exit of hole without additional operation (0.10 mm and bigger)

- Excellent reproducibility of machining results and optimal surface finish thanks to the use of pulsed technology (PECM – Pulsed Electrochemical Machining)

We proudly support you in technology development for your products.

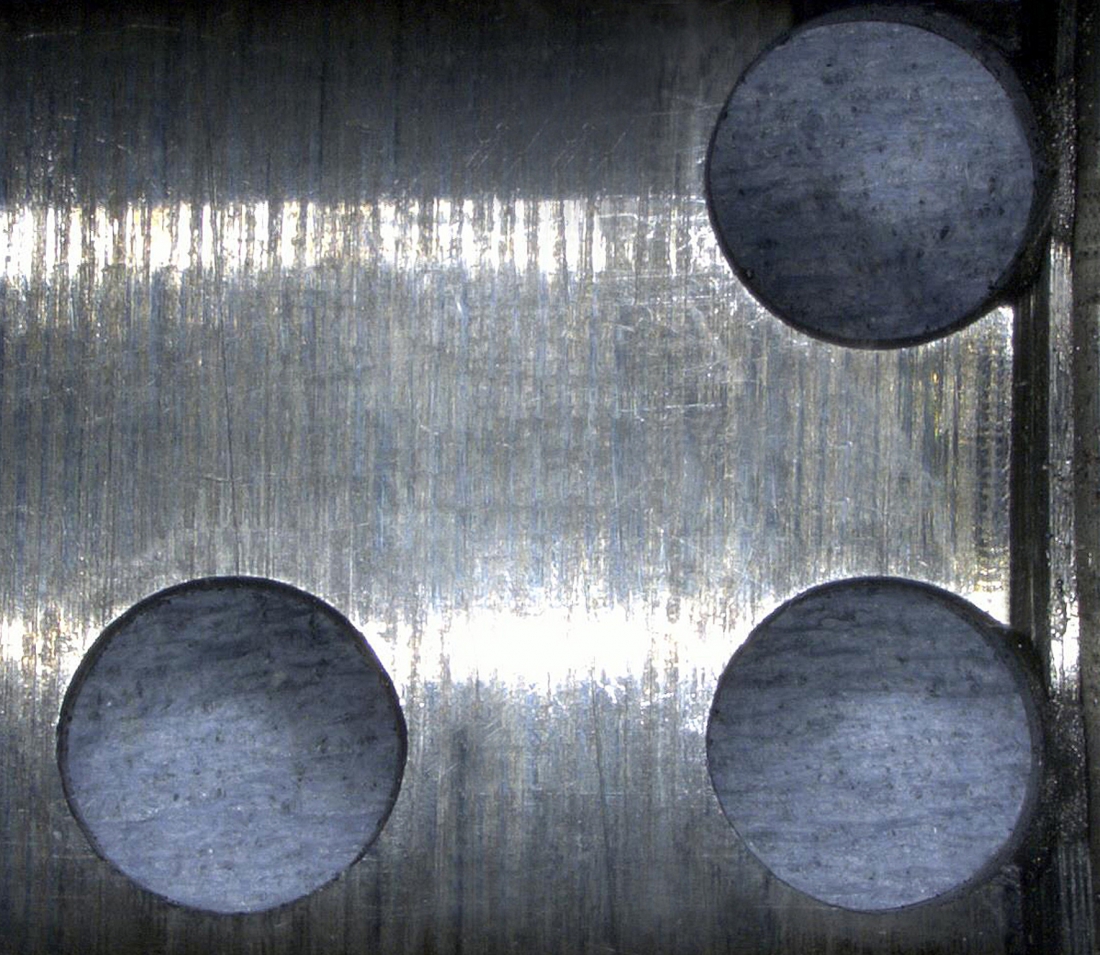

Application example

|

|

|

Sleeve shaft (outlet of hole inside) | 16MnCr5 (1.7131) | 30 holes ø 3,5 with defined chamfer outside and inside | 100s Process time (wall thickness ca. 3mm) | Repeat accurancy ± 0,10mm (position and diameter) |