Forming with ECM-sinking

Electrochemical sinking includes an erosive machining process in which a specially shaped tool is placed opposite to a work piece. Relative cathode movements can be performed. Upon ECM-sinking, the shape of tool is mapped on and/or in the work piece.

Benefits of process:

- Form-machining with utmost precision

- High surface finish and mapping accuracy

- High process speed (up to 3 mm/min and faster) as a function of material and application

- Machining of unalloyed and alloyed steels as well as carbide, titanium, nickel-based and powder-metallurgical alloys

- No process-related cathode wear

We proudly support you in technology development for your products.

Application example

|

|

|

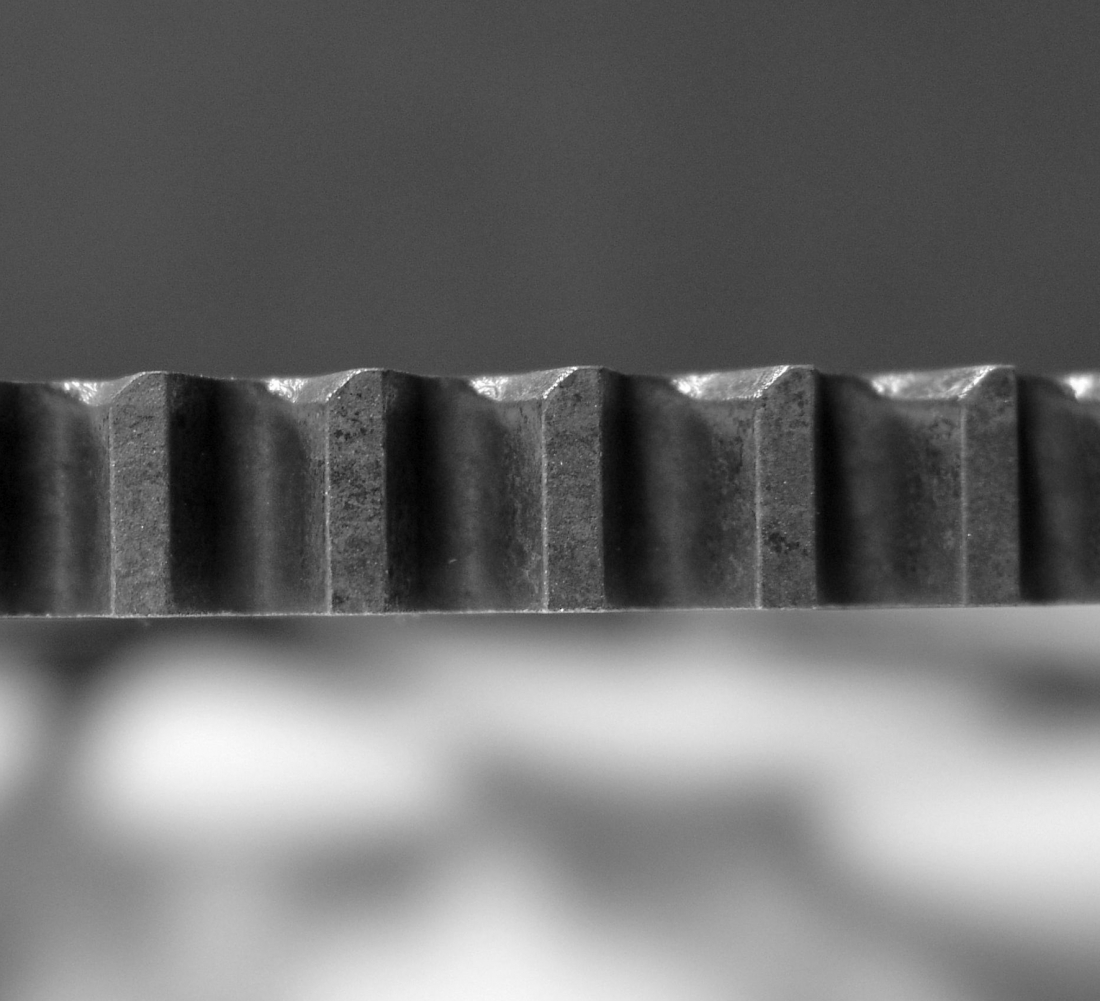

Gear | 37MnB4 (1.5524) | defined chamfer on over 100 cogs | 25s Process time | Repeat accurancy ± 0,02mm |